Flowmeters and Turbine Flowmeters

BackFLOWMETERS

INDUSTRIAL TURBINE FLOWMETERS

HO SERIES PRECISION TURBINE FLOWMETERS

Liquid Service, Inline

Repeatable Flow Range: .0625 to 15,000 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 12″

Gas Service, Inline

Repeatable Flow Range:

.15 to 12,000 ACFM

Accuracy:

+/-1% Linearity

+/-.25% Repeatability

Flowmeter Sizes: 1/4″ to 12

Mini-Flow for Liquid

Repeatable Flow Range: .007 to 3.5 GPM

Accuracy:

+/-1% Linearity

+/-.25% Repeatability

Flowmeter Sizes: 1/2” line sizeMini-Flow for Gas

Repeatable Flow Range: .005 to 1 ACFM

Accuracy:

+/-2% Linearity

+/-.25% Repeatability

Flowmeter Sizes: 1/2″ line

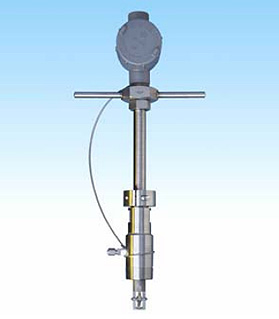

Insertion for Liquid

Repeatable Flow Range: 5 to 250 FPS

Accuracy:

+/-2% Linearity

+/-.25% Repeatability

Flowmeter Sizes: 1/4″ to 12″Insertion for Gas

Repeatable Flow Range: .15 to 12,000 ACFM

Accuracy:

+/-1% Linearity

+/-.25% Repeatability

Sizes: 4″ to 72″ pipe diameters

Liquid Service, Sanitary

Repeatable Flow Range: .25 to 800 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 3″

Liquid Service, Inline

Repeatable Flow Range: .25 to 800 GPM

Accuracy:

+/-1% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 3″

Liquid Service, Inline

Repeatable Flow Range: .45 to 225 GPM

Accuracy:

+/-.1% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 2″

Liquid Service, Inline

Repeatable Flow Range: .35 to 485 GPM

Accuracy:

+/-1% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 3″

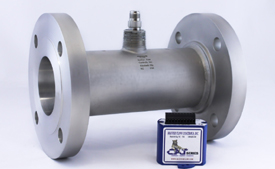

OIL & GAS TURBINE FLOWMETERS

Liquid Service, Inline

Repeatable Flow Range: 4 to 1050 GPM GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1″ to 3″

API Bladed Liquid Service

Repeatable Flow Range: 2 to 1500 GPM

Accuracy:

+/-.25% Linearity

+/-.02% Repeatability

Flowmeter Sizes: 1″ to 4″

Liquid Service, Inline

Repeatable Flow Range: 4 to 12,000 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1″ to 12″

Liquid Service, Inline

Repeatable Flow Range: .2 to 6,400 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 5/8″ to 8″Gas Service, Inline

Repeatable Flow Range: .5 to 4,800 ACFM

Accuracy:

+/-1% Linearity

+/-.25% Repeatability

Flowmeter Sizes: 5/8″ to 8″

SUBSEA SERIES TURBINE FLOWMETERS FOR SUB SEA DEPTHS OF 15,000 FT

Liquid Service, Custom Inline

Repeatable Flow Range: .25 to 15,000 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 12″

TRIFLO SERIES FLEXIBLE MEASUREMENT SOLUTIONS / PRODUCED WATER & HYDROCARBON CONDENSATE

Liquid Service, Inline

Repeatable Flow Range: 4 to 280 GPM

Accuracy:

+/-1% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1″, 1-1/2, & 2″

Gas Service, Inline

Repeatable Flow Range: .15 to 12,000 ACFM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 12″

SPECIALTY TURBINE FLOWMETERS

HHP SERIES HIGH PRESSURE TURBINE FLOWMETERS

Liquid Service, Inline

Repeatable Flow Range: .0625 to 275 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 2″Gas Service, Inline

Consult Factory for Gas

Applications/Sizing.

Flowmeter Sizes: 1/4″ to 2″

AUTOCLAVE SERIES TURBINE FLOW METERS

Liquid Service, Inline

Repeatable Flow Range: .0625 to 35 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 3/4″

Gas Service, Inline

Repeatable Flow Range: .15 to 20 ACFM

Accuracy:

+/-1% Linearity

+/-.25% Repeatability

Flowmeter Sizes: 1/4″ to 3/4″

Liquid Service, Inline

Repeatable Flow Range: .25 to 800 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 3″

Liquid Service, Inline

Repeatable Flow Range: .0625 to 800 GPM

Accuracy:

+/-.5% Linearity

+/-.1% Repeatability

Flowmeter Sizes: 1/4″ to 3″

OPTIONS COMMONLY RECOMMENDED:

calibration provided with all Hoffer Turbine Flowmeters consists of a 10

point, one centistoke calibration over the linear flow range of the meter.

For more viscous applications, a Universal Viscosity Curve (UVC) may be

necessary to document the flowmeter’s performance for viscous service in

order to achieve maximum accuracy.

are available for the Hoffer Sanitary Series and flowmeters with MS flared

end fittings. The kits consist of two lengths of stainless steel tubing

cut to a length appropriate for the up and downstream straight pipe runs.

The kits are suitable for welding into existing pipe lines and can be provided

with NPT or flanged connections. Optional flow straighteners and special

kits to accommodate flanged and NPT meters are available.

Rate Indicator/Totalizers

• Loop or battery powered indicator with data logger.

• 20 point linearization option.

• Configurable thru the ex-proof enclosure via magnetic pointer.

• Dual Set Point Alarm output for rate or total.

• Several enclosure options are available including the explosion-proof enclosure (North America, ATEX & IEX).

• DC, AC, loop or battery powered indicator.

• 20 point linearization option.

• Alarm output for rate or total.

• RS 232 Port for Configuration and Monitoring.

• Windows configuration software.

• Several enclosure options are available including the explosion-proof enclosure (North America, ATEX & IEX).

• LCD display for Total, Rate, Temperature, and Pressure.

• Data logging.

• 20 point linearization option.

• Temperature, pressure, and compressibility compensation.

• AGA-8 compliant.

• Configurable thru the ex-proof enclosure via magnetic pointer.

• Dual Set Point Alarm output for rate or total.

• Several enclosure options are available including the explosion-proof enclosure (North America, ATEX & IEX).

Conditioners, Amplifiers, Totalizers

The CAT1 is a microprocessor controlled 2-wire 4-20mA transmitter

The CAT1 converts a low level, frequency signal from a flowmeter sensor into an analog 4-20mA output. The output is proportional to the flow rate.• Loop powered 4-20mA.

• Optional linearization.

• Windows configuration software.

The CAT2 provides a pulse output and an analog signal proportional to the flow rate. The CAT2 can be configured with high and low alarms.• DC or AC powered transmitter.

• Pulse and analog output.

• Optional hi and low alarms.

The CAT3 is a DC or AC powered, microprocessor controlled transmitter

The CAT3 outputs a pulse scaled per unit of flow, and analog signal proportional to flow rate. The CAT3 can be configured with high and low alarms.• DC or AC powered.• Pulse and analog output scaled per unit of measure.• Flowmeter linearization.

• Optional Hi and Low alarms.

• Windows configuration software.

PET-1, 3, 7 Digital to Analog Converter Mag Type

PET-4, 5, 6 Preamp Signal Conditioner Mag Type

It has been designed to fit a compact “ELBY” explosionproof enclosure.

This series is designed for use with the Lo-Co Series low cost flowmeters.

• PET-1 0 to 10 VDC analog output.

• PET-3 4 to 20 mA analog output 3 wire.

• PET-7 4 to 20 mA analog output 2 wire with improved EMI noise immunity.

The signal conditioners are built to fit a compact “ELBY” type explosion-proof enclosure.

• PET-4 TTL/CMOS (0-5 VDC)

• PET-5 0-10 VDC Square Pulse.

• PET-6 Open Collector.

Cryogenic Systems

ICE Integrated Cryogenic Electronics

The ICE is Hoffer’s most advanced truck-mounted cryogenic flow metering system. ICE is a microprocessor-based totalizer designed to withstand the rigors and weather conditions imposed on truck-mounted, over-the-road cryogenic systems. Some features include: user friendly software, preventive maintenance notification and system malfunction detection.

An optional point-of-sales printed delivery ticket is available as well as a number of software options offering flexibility, customization and future expansion. The full color graphical display and electronic touch screen ensure user-friendly operator interface and provide direct access to all measurement and configuration parameters including total, rate and temperature.

Designed in compliance with O.I.M.L.—R81 standard, Handbook 44 and various design approvals.

The Hoffer Cryogenic truck-mounted cryogenic flow metering system has been designed to withstand the rigors of over-the-road service and to operate reliably in the accompanying temperature extremes they will see in actual service. Hoffer Cryogenic systems allows for superior performance and ease of use. The system provides accurate measurement of commonly delivered industrial gases while having printer output capability. The system requires minimal operator involvement. The cryogenic system provides advanced reporting and communication capabilities including reporting for delivery, trip and maintenance via Hoffer printers or computer communication. Designed to comply with O.I.M.L.—R81 standard, Handbook 44 and various design approvals.

Hoffer offers a variety of cryogenic printers available for your Hoffer cryogenic system depending on your needs and specifications.

Whether you need your printer shock mounted, water-proof or portable and lightweight, we have an option for you.

Our P9 printer even offers printer capabilities in a wireless Bluetooth® design.

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.