Turbine Flow Meters

Turbine Flow Meters, Flow Meters

Flowmeter Selection Criteria to Optimize the Turbine Flowmeter Advantage

Turbine flow meters measure the velocity of liquids, gases, and cryogenic fluids. Typical fluids and gases measured with turbine meters include hydrocarbons, chemicals, water, cryogenic liquids, air, natural gas, and industrial gases. Hoffer turbine flowmeters are simple to operate and maintain. For this reason, Hoffer turbine flow meters can be found in service worldwide and are regarded as a reliable, cost-effective method for achieving high accuracy flow measurement.

In recent years, new markets and industries have developed for turbine flow meters. These new growth markets include aerospace, military flow applications, chiller systems, and many others. Features on the Hoffer turbine flow meters that are important in these growth markets include dynamic response time, wide flow range capability, and the ability to customize the turbine flow meter for a specific flow application. Custom features may include the design of the flow meter housing, a unique blade angle on the turbine meter rotor assembly, special materials of construction, etc.

[ READ MORE + ]

Hoffer Flow Controls offers the most extensive selection of turbine flow meters compared to any other flowmeter manufacturers globally. Our MF Series of mini-flowmeters provides flow measurement capability from .007 to 3.5 GPM and offers twelve different turbine meters.

Our HO Series provides ¼” through 12” turbine flow meters for service in either liquid or gas. In addition to the MF Series and HO Series, we provide 20+ specialty series of turbine flow meters.

These specialty series enable Hoffer to offer flow meters suitable for the oil & gas industry, power generation industry, cryogenic industry, military flow applications, and aerospace.

Popular specialty turbine flow meter series include our Grayloc, high-pressure flow meters, the Wafer Series, the Autoclave Series of high-pressure turbine meters, the Subsea Series, and the API Series for custody transfer grade performance and meter resolution (K-factor).

The turbine advantage may be defined as the unique blend of desirable attributes peculiar to the Hoffer type turbine flowmeter resulting in a transducer with the ability to measure wide flow ranges with outstanding accuracy, at low cost, with a convenient pulse output.

Flowmeter selection requires more than the sizing of flow rates and selection of process fittings. The turbine flowmeter must be compatible with the flowing media to be measured and operate over the required temperature and pressure range.

In addition, maintenance requirements must be evaluated consistent with the installation, service, and use. The following tutorial provides the background information required for the selection of a Hoffer turbine flowmeter. Whatever your flow requirements may be, Hoffer offers the optimum turbine flowmeter for the specific application.

Operation

Within the Hoffer turbine flowmeter, the flowing media engages a vaned rotor causing it to rotate at an angular velocity proportional to flow rate. The pickup coil senses the spinning motion of the rotor through the housing and converts it into a pulsing electrical signal. The summation of the pulsing electrical signal relates directly to the total flow, while the frequency is linearly related to flow rate.

Performance Characteristics

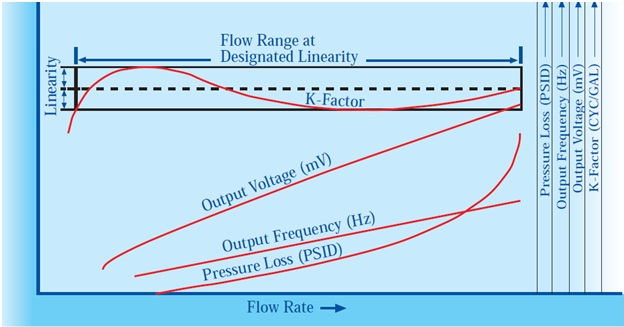

The K-Factor is the number of output pulses the flowmeter produces per engineering unit of volume thru-put. The Linear Range is that flow range over which the K-Factor is constant within the specified limits of linearity. Linearity is a measure of the accuracy of the device. The maximum percentage deviation from the average-Factor, K.

The linearity of all Hoffer turbine flowmeters is stated as a percent of reading. Most other metering devices state linearity as a percent of full scale, which implies a derated accuracy.

Each Hoffer turbine flowmeter is individually calibrated, and the resulting performance characteristics are presented in a computerized tabular format. The repeatability of a turbine flowmeter measures the stability of the output under a given set of flow conditions. The repeatability is defined as the allowable percentage deviation from the stated K-Factor at that flow rate.

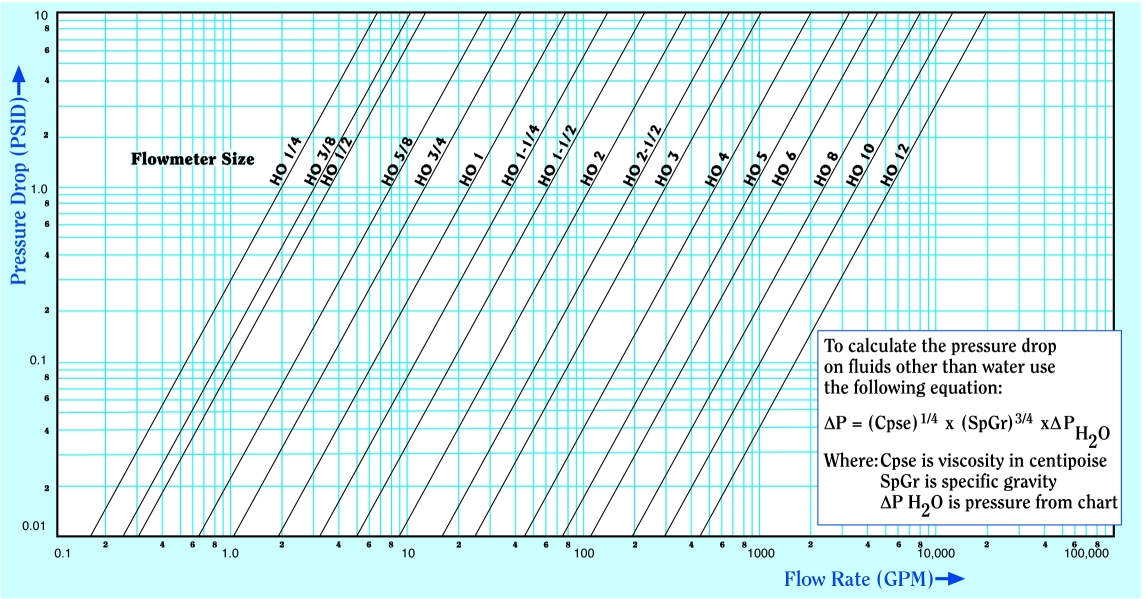

For Hoffer flowmeters, the repeatability is many times smaller than the linearity error, inferring a much greater accuracy if the known flow rate dependency of the K-Factor is eliminated by using an external linearizing device. The turbine flowmeter is an intrusive flow measurement device, and therefore the pressure drop characteristic is an important consideration.

Installation

Hoffer turbine flowmeters may be mounted in any orientation and are generally supported by the process connections. A wide variety of process connections are available on Hoffer turbine flowmeters to suit almost any application. Allow an inlet straight pipe run of at least 10 pipe diameters and outlet pipe run of 5 diameters (minimum) of the same size as a flowmeter. Turbine flowmeters 3/4” and smaller should have 10” upstream and 5” downstream of the same size pipe as a flowmeter.

Material Selection & Construction

Hoffer turbine flowmeters are available in a broad range of standard and special materials. The wide range of construction options allows for selecting the optimum combination of useful range, corrosion resistance, and operating life for a particular application.

A low mass rotor design allows for a rapid dynamic response which permits the turbine flowmeter to be used in some pulsating flow applications. The deflector cones eliminate downstream thrust on the rotor and allow hydrodynamic positioning of the rotor between deflector cones.

The hydrodynamic positioning of the low mass rotor provides wider rangeability and longer bearing life than that of conventional turbine flowmeters. Integral flow straightening tubes minimize the effects of upstream flow turbulence. The housing is made of non-magnetic materials. The rotor is made of magnetic or magnetized material. Bearings are chosen based on media service, cost, and accuracy considerations.

Standard materials of construction are 316 stainless steel for the flowmeter body and rotor supports. The rotor materials of construction include 17.4 PH SS, Nickel 200, and 430 SS. Many special materials are available, some of which include Teflon®, 4130 Steel, Monel, other grades of stainless steel such as 304, Hastalloy, titanium, tantalum, and numerous other exotic materials.

The selection of the construction materials is usually dictated by media compatibility, availability, and cost considerations. Our application engineers stand ready to assist every user in the selection of material, as well as recommending a bearing type compatible with the intended service environment.

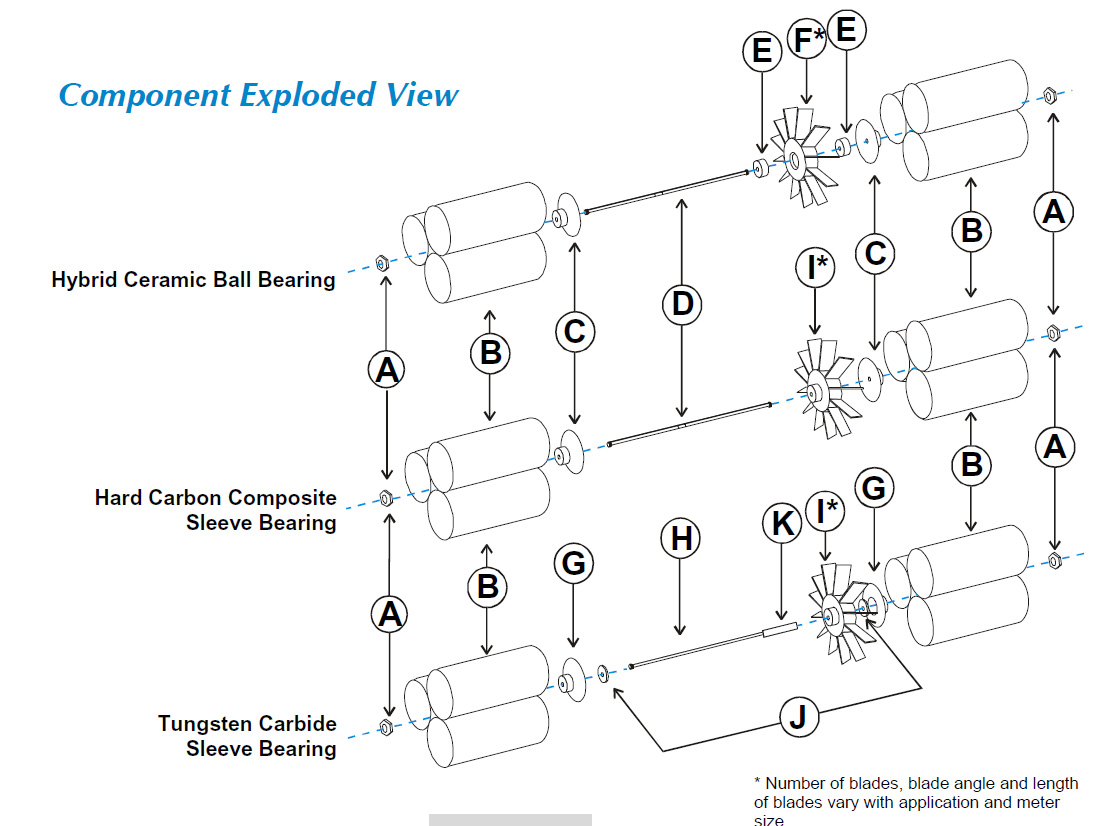

Bearing Selection

Many bearing types are available, including ball bearings and sleeve type construction in tungsten carbide, hard carbon composite, Teflon®, and carbon graphite composition. When selecting several chemically compatible bearings, the ball bearing design offers the highest accuracy and generally has the widest usable range. It remains the bearing of choice in many fluids and is required for gas flowmeters.

Tungsten carbide and hard carbon composite offer the most durable bearing materials in service fluids in which they are compatible. These represent the standard bearing type for many industrial service environments. Hard carbon composite sleeve bearings offer properties nearly chemically inert to many corrosive fluids and are utilized primarily for this reason. In turbine flowmeters, the flowing fluid provides bearing lubrication in most applications.

It may be observed that fluids that offer a high natural lubricity tend to prolong the life of the flowmeter. Many bearing types offer advantages in that they provide self-lubrication as well as providing a wear-resistant surface. Among these bearing materials are carbon graphite composites and some ball-bearing designs.

Bearing life is approximately inversely proportional to the square of the bearing speed. To prolong the life of the turbine flowmeter, it is advantageous to operate the flowmeter at rates less than the maximum flow rate. For example, if the turbine flowmeter is operated at 1/3of the maximum flow rate, it will wear at approximately 1/10 the rate.

Flowmeter Pickup Selection

The flowmeter pickup senses the motion of the rotor and converts it to a pulsing electrical signal which is of a discrete, digital nature. Hoffer Flow Controls offers several pickup types suited for different applications. The advantages of each are listed in the following discussion.

High Output Magnetic Pickup Typical Range

10:1 (Self Generating)

The standard pickup for turbine flowmeters 1 inch and larger produce a high-level sinusoidal output. To produce this, the pickup generates a relatively high magnetic field. The signal may be transmitted to 200 feet without amplification. A flow range of 10:1 or better is common with this pickup type.

Low DragMagnetic Pickup Typical Range

25:1 (Self Generating)

Low drag magnetic pickups may be used to obtain a flowmeter range of 25:1 or better. They offer a significant reduction in drag effects with lower output levels and may require preamplification before transmission. Low drag magnetic pickups are used extensively in meter sizes below 1 inch.

Magnetic Pickup Output Signal Characteristics

The output signal voltage of the magnetic coil is approximately sinusoidal. The frequency range of the pulsing signal varies from size to size. Standard ranges allow maximum output frequencies at the nominal maximum linear flow of 250, 500, 750, 1000, 1500, 2000, and 2500 Hz. The amplitude of the output signal is a function of flow rate.

The voltage at the minimum linear flow is greater than 30 millivolts peak to peak when measured into a 10,000-ohm load. On larger size flowmeters, the output level may exceed several volts peak to peak. The DC output resistance of magnetic pickup coils is less than 2000 ohms. Detailed impedance characteristics are available upon request. F

Modulated Carrier Pickup Typical Range

100:1 (MCP)

The Hoffer MCP pickup is an active coil that eliminates pickup drag and requires a Modulated Carrier Signal Conditioner to be mounted on or near the flowmeter. The MCP works on the principle that the motion of the motor modulates a high-frequency signal. The conditioner demodulates, filters amplify and shapes the resulting signal before transmitting it as a high-level signal.

The use of the MCP pickup allows for wider flow ranges than can be achieved with the low drag magnetic pickups. The cost compares with that of a preamplifier for a magnetic pickup. This pickup type is used extensively when a wide flow range is required or with flowmeters that are being used with a universal viscosity calibration curve (UVC).

Typically, MCP coils can obtain flowmeter ranges of up to 100:1. Hoffer offers a complete turbine flow meter electronics line that provides flow meter linearization over the 100:1 turndown range. This powerful feature improves the flow meter accuracy from +/-0.5% to +/-0.1% reading on the HO series of liquid meters.

Redi-Pulse Pickup In Magnetic & Modulated Carrier Types

The Redi-Pulse pickup coil includes a self-contained preamplifier which provides a conditioned pulse output, eliminating the need for peripheral signal conditioning modules and associated junction boxes. Turbine flowmeters specified with the magnetic coil will provide the user with a turndown range of 10:1 to 25:1 depending on meter size and type of bearings specified.

Turbine flowmeters specified with the modulated carrier coil will provide the user with a usable flow range up to 100:1 when the turbine is specified with ball bearings. A conditioned pulse output signal may be transmitted up to 3,000 feet.

The Redi-Pulse pickup coil provides users with an option when size/weight is an issue and provides greater noise immunity when transmitting through a noisy environment. The Redi-Pulse is certified with the CE mark for compliance with EMC Directive 89/336/EEC.

Quadrature Output Option

When a Hoffer turbine flowmeter is equipped with two pickup coils properly positioned on the flowmeter housing, it is possible to sense flow direction, flow rate, total flow, and add and subtract options. The pickup coils generate two output signals with a quadrature (90°) phase difference.

With suitable electronic phase discriminating circuitry, it is possible to provide two separate output signals related to flow in the forward direction only, with the second related to flow in the reverse direction only.

Unlike many other turbines, Hoffer turbine flowmeters are built physically symmetrical, which inherently makes bi-directional flow measurement possible with only the addition of a second pickup, keeping costs considerably less than other manufacturers.

Other considerations which may dictate equipping two pickup coils on a single flowmeter arise from advantages in the ease of achieving parallel signal processing or increased reliability. A Hoffer electronic system is also available for sensing pickup coil failure.

Hazardous & Weatherproof Environmental Coil Enclosures

The explosion-proof requirements of UL Class I, Groups B, C and D, Class II, and NEMA 4X are routinely provided by enclosing the pickup coil in suitable housing. Signal conditioners and converters can readily be mounted on the flowmeter in a suitable enclosure.

Unlike most other flowmeter types, Hoffer turbine flowmeters are inherently safer since they require no through holes, eliminating the possibility of a leak. Hoffer can provide flow systems that are certified to CSA/FM and ATEX IECEx requirements.

I.S. Flow Systems

An increasing number of process industry applications require intrinsically safe flow systems. To accommodate this growing need, several Hoffer flow systems are available with I.S. certification.

Specifying Flowmeter Calibrations

The standard calibration provided with all Hoffer turbine flowmeters consists of a 10 point water calibration over the linear flow range of the meter. Many optional flowmeter calibrations may also be requested. A 10 point water calibration over the extended range of the meter may be requested at no additional charge.

Additional calibration points may be requested within the linear range or in the extended range at additional cost. Fluids other than water are used to simulate viscosity conditions from 2 to 300 centistokes. Where it is necessary to document the flowmeter’s performance for viscous service, the flowmeter calibration simulates the viscosity and the flow rates anticipated in actual service.

Universal viscosity calibration (UVC) curves may be documented for each Hoffer turbine flowmeter. This information is required to achieve maximum flowmeter accuracy in medium to high viscosity service (See Figure 2). In general, any flowmeter size may be supplied with a universal viscosity curve; however, since smaller meter sizes (under one inch) display the largest calibration factor sensitivity to viscosity, this size range is the most likely to be considered for a universal viscosity curve.

The universal viscosity curve may be utilized to determine the K-Factor graphically or algorithmically for a measured set of flow conditions in the case of an intelligent instrument. Hoffer offers a standard viscosity calibration which consists of ten points for each viscosity required.

A typical UVC curve requires three sets of ten points plotted on graph paper as a continuous curve. In addition, Hoffer offers a 10 point calibration and viscosity curve on a turbine flowmeter at a single viscosity (up to 300 centistokes) at an additional charge.

Size Selection for Liquid Flow Measurement

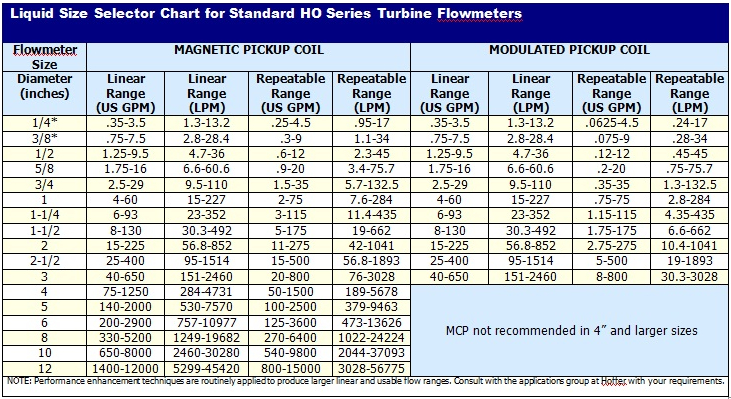

The flow measurement range capability of the Hoffer HO series is from .0625 to 15,000 GPM in 17 overlapping ranges. Meter size selection is accomplished with the aid of Chart 1. Flow rangeability requirements often dictate the pickup and bearing type to be used. Note that sleeve bearing selections may reduce the flow range data listed in the flow meter size selector chart but offer extended operating life benefits.

User preference and temperature/pressure considerations determine the turbine flowmeter configuration, and process end fitting types are determined by user preference and temperature/pressure considerations. Standard end fittings include NPT, MS Flared, and flanges in ANSI and DIN standards.

[ CLOSE – ]

Industrial Turbine Flowmeters:

HO Series for Liquid Turbine Flow Meters

Turbine flowmeters, Liquid precision flow measurement

HO Series for Gas Turbine Flow Meters

Turbine flowmeters, Gas precision flow measurement

Hoffer Mini-Flow Meters for Liquids & Gases

Flowmeters, Turbine flowmeter Liquid & Gas

HP Insertion Series Turbine Flow Meters for Liquids & Gases

Turbine flow meters liquids & gases, Insertion flowmeters

Sanitary Turbine Flowmeters

Industrial Star Series Turbine Flow Meters for Liquids

Turbine flowmeters – Liquid flow metering

Lo-Co Series Turbine Flow Meters for Liquid

Turbine Flowmeters, Liquid Flowmeters

Teflon Series Turbine Flow Meters for Corrosive Service

Flowmeters, Anti-Corrosive flowmeters

OIL & GAS TURBINE FLOWMETERS:

API Series Turbine Flow Meters for Custody Transfer – Bladed Rotors 1″ – 4″

Turbine Flow Meters, API Series Custody Transfer

CT Series Turbine Flow Meters for Custody Transfer – Rimmed Rotors 4″ – 12″

CT Series Turbine Flow Meters for Custody Transfer

Grooved flowmeters, Turbine flowmeters

Premier Gas Series Turbine Flow Meters

Turbine flowmeters, Gas Flowmeters

Subsea Turbine Flowmeters

Tri-Flo Liquid Turbine Flowmeter

Tri-Flo Meter, Turbine Flowmeters

HO Series for Wafer for Liquid Service Flow Meters

HO SERIES WAFER, Turbine Flowmeters Liquid Service

HO Series for Wafer for Gas Service Flow Meters

HO SERIES WAFER, Turbine Flowmeters for Gas Service

Wing Nut Turbine Flow Meters High Pressure for Liquid

Wing Nut High-Pressure Flowmeters, Turbine Flowmeters Liquid Service

4″ Wing Nut Turbine Flow Meters High Pressure for Liquid

Turbine Flowmeters Liquid Service, 4 inch Wing Nut High-Pressure Flowmeters

Wing Nut Turbine Flow Meters High Pressure for Gas

Wing Nut High-Pressure Flowmeters, Turbine Flowmeters Gas Service

SPECIALTY TURBINE FLOWMETERS:

Autoclave Turbine Flow Meters for Liquid Service

Autoclave Turbine Flow Meters for Liquid Service

Autoclave Turbine Flow Meters for Gas Service

Autoclave Turbine Flow Meters for Gas Service

HHP Series, High-Pressure Turbine Flow Meters For Liquids & Gases

High-Pressure Flow Meters for Liquid and Gas (HHP Series)

HO Liquid Turbine Hose Series/Barbed & Beaded Flow Meters

Turbine Flowmeters, Barbed – Beaded Hose Flowmeters

Steam Jacketed Turbine Flow Meters For Liquids

Turbine Flowmeters for Liquids, Flanged Steam Jacketed HO Series

H.O.G. Hoffer Oval Gear Positive Displacement Flow Meters

Positive Displacement Flowmeters, Hoffer Oval Gear Series

HO Series Spare Internals and Parts

Turbine Flowmeters Spare Internals and Parts

Please follow Hoffer Flow Control on Linked In

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News