Purified Water Flowmeter | Pharmaceutical WFI Water

Purified Water Flowmeter, Sanitary Flowmeters, WFI flowmeter

Hoffer Helps Pharmaceutical Giant “WFI” Headache

Ultrapure deionized water is commonly used in the healthcare industry to manufacture eye drops, nose spray, and hygiene products. This highly purified water sometimes referred to as “WFI” (Water for Injection) or compendial water, presents many challenges for a flowmeter.

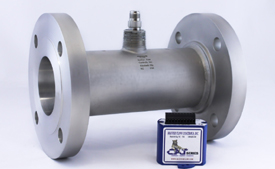

WFI is non-conductive, corrosive to certain metals in nature, and requires a sanitary-style flowmeter. The Hoffer Sanitary Series flow metering products meet the requirements and are used routinely throughout the industry with excellent results. The BPE-compliant sanitary design, 316 stainless steel construction, and wide turn-down make the Sanitary Series an excellent solution for a WFI application.

“CIPable” or suitable for “Clean in Place

Pharmaceutical industry standards require that all flow measurement and other process devices be fully “CIPable” or suitable for “Clean in Place.” This means that the flowmeter must be fully cleaned when flushed with a suitable cleaning product or steam.

The Hoffer Sanitary Series of turbine flowmeters incorporates a design that is fully cleaned when flushed. Furthermore, this series of flowmeters are available with a hard carbon composite sleeve bearing suitable for steam cleaning.

One Hoffer customer, an international manufacturer of healthcare products who employs 54,000 people looking for a solution to a problem, came to Hoffer to discuss a WFI application. The flowmeters then used in their WFI process were routinely being replaced.

The cast internal assembly with a Rulon sleeve bearing was deteriorating after a few (CIP) cycles. The downtime, replacement cost, and potential contamination from a deteriorated set of internals required immediate attention and a quick resolution from their maintenance personnel.

The customer determined that the Hoffer Sanitary Series turbine flowmeter was the most accurate and cost-effective solution for the application.

Sanitary Series provides Flow Measurement

The Sanitary Series provides flow measurement capability from .35 to 650 GPM in flowmeter sizes ranging from 1/4″ through 3″. The Sanitary turbine flowmeter provides a turndown range of 10:1 to 40:1 depending on flowmeter size. A clamp-type sanitary process connection is standard.

The meter is fully “CIP-able.” Construction consists of 316/316L dual rated stainless steel body and hangers, 17-4 ph stainless steel rotor, and a carbon composite sleeve bearing.

Hoffer is pleased to provide sanitary flowmeters for the healthcare industry. If your facility uses deionized, demineralized, or WFI water, contact us to help with your flow measurement needs. Let our 50+ years of experience in flow measurement become your resource.

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality liquid turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Control on Linked In

Purified Water Flowmeter from Hoffer Flow Controls

Hoffer Turbine Flowmeters are available in a broad range of standard and special materials. The wide range of construction options allows for selecting the optimum combination of useful range, corrosion resistance, and operating life for a particular application. A low mass rotor design allows for a rapid dynamic response which permits the turbine flowmeter to be used in pulsating flow applications.

Also, see

What are the best applications for turbine flowmeters?

Sanitary Flow Meters

What is required to size gas turbine flowmeters?

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News