LNG Flow Measurement

Hoffer has a long history of supplying cryogenic flow measurement systems on bulk delivery tankers for LIN, LOX, LAR, and CO2. Given our experience in this niche industry, it was only natural that our flow measurement solutions for tanker transports would expand to enable us to offer turbine flow meter-based flow products for use on LNG.

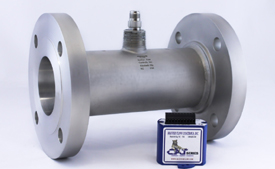

As a result, the flow system components we supply for tankers delivering LNG for custody transfer typically include a flanged turbine flow meter, a pressure sensor, and a temperature sensor. The most critical component we supply for LNG measurement is the ICE cryogenic flow computer.

Custody transfer flow transaction

This ICE flow computer is designed, built and calibrated by our company. Given that bulk delivery of LNG by a tanker to an end-user (customer) is a “custody transfer” flow transaction, the flow system must comply with regulatory standards appropriate for the product being sold.

For LNG transactions in the United States, the flow system must comply with Handbook 44 and NTEP approval. Additionally, ICE also meets the requirements of OIML R81 and OIML R117 with many international approvals, including MID (European Union), NMI (Australia), SIRIM/NMIM (Malaysia), NRCS (South Africa), MBIE (New Zealand), and the government of India.

LNG flow systems using the turbine flowmeter

Essentially, the principle of operation for the LNG flow systems is using the turbine flowmeter. Specifically to obtain an accurate volumetric rate of flow of the LNG being delivered. Secondly, the use of the RTD sensor to accurately measure the temperature of the LNG being delivered.

Thirdly, the pressure sensor to determine the pressure of the LNG being delivered. After that, all three signals are transmitted to the ICE cryogenic flow computer. At that point, the computer integrates the flow rate signal over time to determine the total volume of LNG delivered.

The flow computer uses the temperature and pressure signals to determine the density of the LNG in real-time against pre-loaded LNG fluid property tables. Finally, by knowing the volumetric total flow and the density of the LNG, the total mass or compensated volume of the LNG delivered can be determined within the legal requirements.

Lastly, the Hoffer ICE cryogenic flow system on LNG is available in multiple languages and supports English, Spanish, French, German, Polish, Czech, and Portuguese.

LNG Flow Measurement from Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today, our reputation in this field is synonymous with quality.

In addition, Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Controls on Linked In

Also, see

Turbine flow meters

Cryogenic Flowmeters

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News