Hydraulic flowmeters | Brewery in Midwest

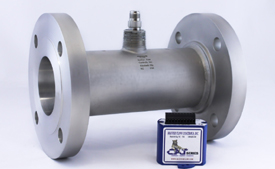

Hydraulic flowmeters | Sanitary flowmeters for pure water hydraulic flow meter applications

Brewery in Midwest – This Brew’s For You

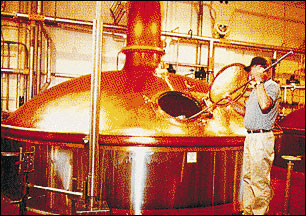

Did you know that Hoffer turbine flowmeters are used in the brewing process by an Internationally recognized company with a significant share of the beer market? While the ingredients used in the brewing process have not changed significantly over the years, automation and state-of-the-art control capability have provided exacting standards for superb product quality control.

A critical part of the brewing process occurs after “mash” has been created. This mash, consisting of water and grain, is transferred to a Lauter Tun settling tank. The Lauter Tun, a large diameter flat bottom vessel, separates the wort, the sugar solution, from the grain. Inside this Lauter Tun is a rake used to stir and level the grain as it settles to the vessel’s bottom.

The rake is operated hydraulically using filtered pure water. The Hoffer turbine flowmeter is used to monitor the filtered pure water flow. The use of the filtered pure water is for sanitary reasons, which assures that if a leak were to occur in the rakes hydraulic system, the only thing that could make contact with the wort would be the pure water.

Once this separation is completed, the wort is pumped out of the vessel for fermentation. Cleaning water is added to the separator vessel, and the rake again stirs the grain as the water and used grain are pumped out. The cleaned vessel is then ready for the next batch.

The specifying engineer at the brewery selected the 1″ Hoffer turbine flowmeter for use on the pure water hydraulic flow application. Hoffer was specified due to the need for high accuracy and repeatability over a wide flow range. The repeatability and accuracy at the low flow rates are critical because the flow is alarmed for low flow conditions. This allows the customer to check for a leak in the system or a possible malfunction should an alarm occur.

Another important feature of the Hoffer turbine flowmeter is the all stainless steel construction to maintain the high purity level of the water. All lines in the hydraulic system are also stainless steel. Multiple 1″ Hoffer flow systems have been installed in this large mid-western brewery for this critical application.

After straining is completed, the brewing process is kettle brewing, cooling, fermentation, and finishing. Beer is “big business,” To give you an idea to what extent, check this out. 16 million 12 ounce beers are produced on an average day by this large mid-western brewery. That’s a lot of brewskies!

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Control on Linked In

Also, see Sanitary Turbine Flow Meters and Sanitary Flow Meters

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News