Oil Aerosol Flowmeter, Mini-Flow Turbine Flowmeters | Steel Mills

Oil Aerosol Flowmeter, Mini-Flow Turbine Flowmeters

Steel Mills Industry: Blast furnaces and steel mills

SIC Code: 33X12

Application:

Oil Aerosol Flowmeter | To monitor oil spray on the top and bottom of a continuous feed steel sheet for quality assurance and optimization of oil coating. In addition, to monitor return flow of unused oil to a storage tank to provide total oil used. Steel manufacturers use oil at various stages in the process of making steel. Some examples of specific uses follow: Oil, in combination with water, may be used as a cooling agent to quench steel that has been subjected to intense heat. It may be applied to the surface of steel for rust protection or to prevent scoring in case the steel rubs together.

System Requirements:

An oil supply monitoring system used in the sheet steel industry should be accurate and repeatable, but it must be reliable. During processing, lack of oil on the steel sheets may fail the processing machinery, causing expensive downtime or poor quality steel.

The flow monitoring system must measure the total spray via multiple lines and the excess oil collected in the sump and returned to storage. A multi-input flow computer is also needed to provide instantaneous rate and total for each line.

Solution:

Hoffer Mini-Flow turbine flowmeters

Three Model MF1/2X50B-.023-.2-B-1M-MS each with ten points NIST traceable calibration.

Two Mini-Flowmeter linearizers ACC22B-1-X-7-D-PS-4H/O

One Flowstar Model 2000-A-D7-R2-1-3-M-(2-7)-1-HO/LO-P-X Flow Rate

Indicator/Totalizer. Accepts simultaneous inputs from all three mini-flowmeters.

Three Flared Installation Kits Model FIK-1/2-UD10X5-1/2MNPT-X-X

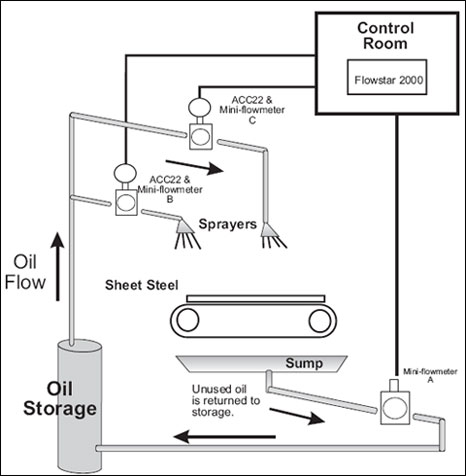

The equipment above works as a system in the following process: Channel 1 of the Flowstar will accept the pulse output directly from turbine meter “A,” which is to be installed in the sump return line to provide an instantaneous rate plus a running total of unused oil which is returned to the storage tank.

Channel 2 and 3 of the Flowstar will accept the linearized 4 to 20 mA output signal from the two ACC22B linearizers mounted on the two turbine meters “B” and “C.” Both flowmeters supply oil used to coat the steel. The Flowstar 2000 will provide the instantaneous rate and total of each line.

Hoffer Advantage:

The Flowstar 2000 has two analog outputs, which may be used to provide outputs to remote displays. The standard digital output may be fed to the computer to provide mathematical functions such as top to bottom flow differential, total oil usage per run, etc. The Flowstar 2000 also has two standard relay contact outputs, which may be configured for alarm setpoints for either high or low flow rates or total. The system has the ability to provide output to an intelligent controller to provide automated flow control. This system provides high accuracy and instantaneous rate, and total readouts in a convenient single location.

Summary:

The system, installed in a major steel manufacturing facility, accurately monitors oil spray onto the top and bottom of a continuous feed sheet. The system also monitors the return flow of unused oil to a storage tank and, via the Flowstar 2000, provides the user with flow rate and total for three flowmeters. Through the Hoffer flow metering system, the customer’s needs of quality assurance and optimization of oil coating are met.

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality liquid turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Control on Linked In

Oil Aerosol Flowmeter from Hoffer Flow Controls

Hoffer Turbine Flowmeters are available in a broad range of standard and special materials. The wide range of construction options allows for selecting the optimum combination of useful range, corrosion resistance, and operating life for a particular application. A low mass rotor design allows for a rapid dynamic response which permits the turbine flowmeter to be used in pulsating flow applications.

Also, see

Gas Turbine Flowmeters, Wing Nut High-Pressure Flowmeters

Subsea Oil and Gas Flow Metering Products

HIT4G Digital Gas Flow Computer with Modbus and Data Logging

HIT-4L Temperature & Pressure Flow Computer For Liquids

HIT-4U Rate Indicator Dual Totalizer with Modbus and Data Logging for Liquids

What is a turbine flowmeter?

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News