Who is Hoffer Flow Controls?

- Founded in 1969 by Kenneth R. Hoffer

- Privately-held corporation located in Elizabeth City, NC.

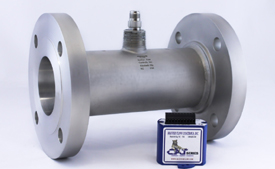

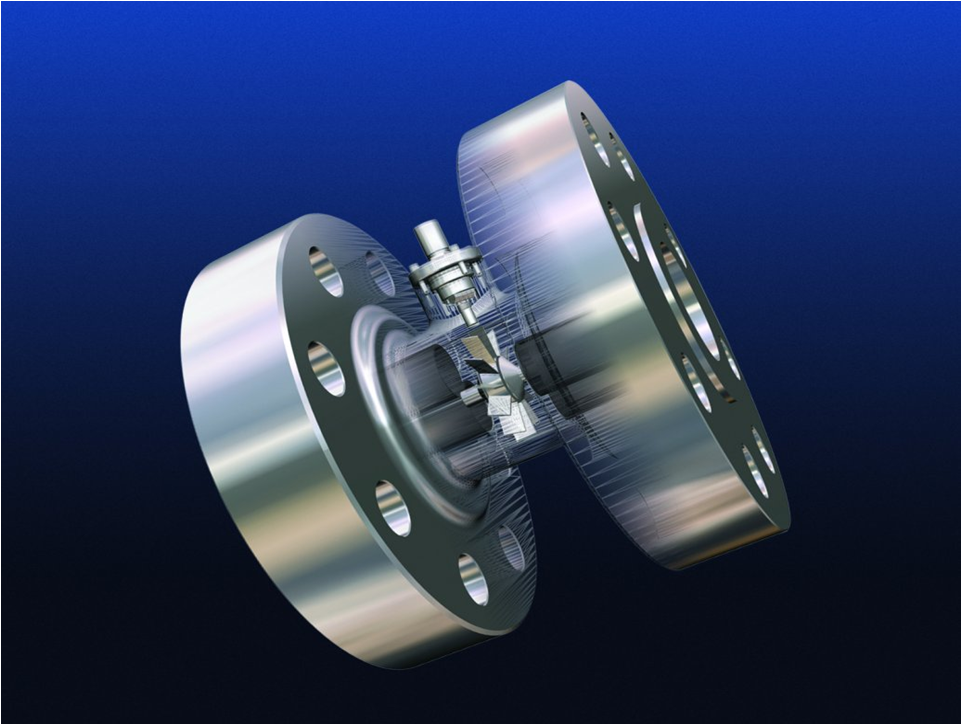

- Noted manufacturer of turbine flow meters for liquid, gas, and cryogenic flow measurement.

- Vertically integrated manufacturing facilities including…

- Machine Shop

- Fabrication Shop

- Hydrostatic & Dye Penetrant Shop

- Electronic Assembly & Test Shops

- Flow Meter Calibration Shop Accredited to 17025

Hoffer Flow Controls Machine Shop

- Upstream Oil & Gas E&P

- Downstream Oil & Gas Custody Transfer

- Cryogenic Custody Transfer

- Power Generation/Energy Management

- Pharmaceuticals & Biotech

- Military (US Navy, US Army & USAF)

- Aerospace

- Automotive

- Currently offering more than 20 series of flow meters for industrial, commercial, and military applications.

- Actively sold to more than 60 countries.

- 40% to 50% of annual sales are exported outside the U.S.

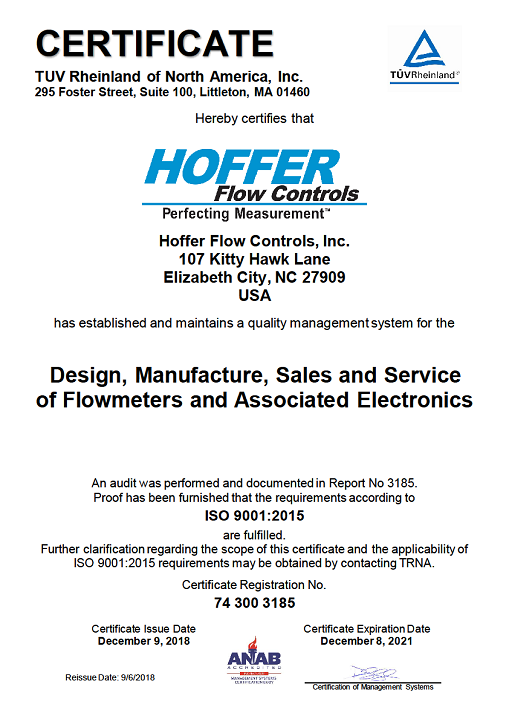

Our systems meet or exceed the following standards:

- ISO 9001

- PED 2014/68/EU

- ISO 17025

- ATEX Directive 2014/34/EU

- NIST Hand Book 44 USA

- OIML, R-81-World

- CSA – Canada

- NIST – USA

- PTB – Germany

- CE Standard – Europe

- Dantest – Denmark

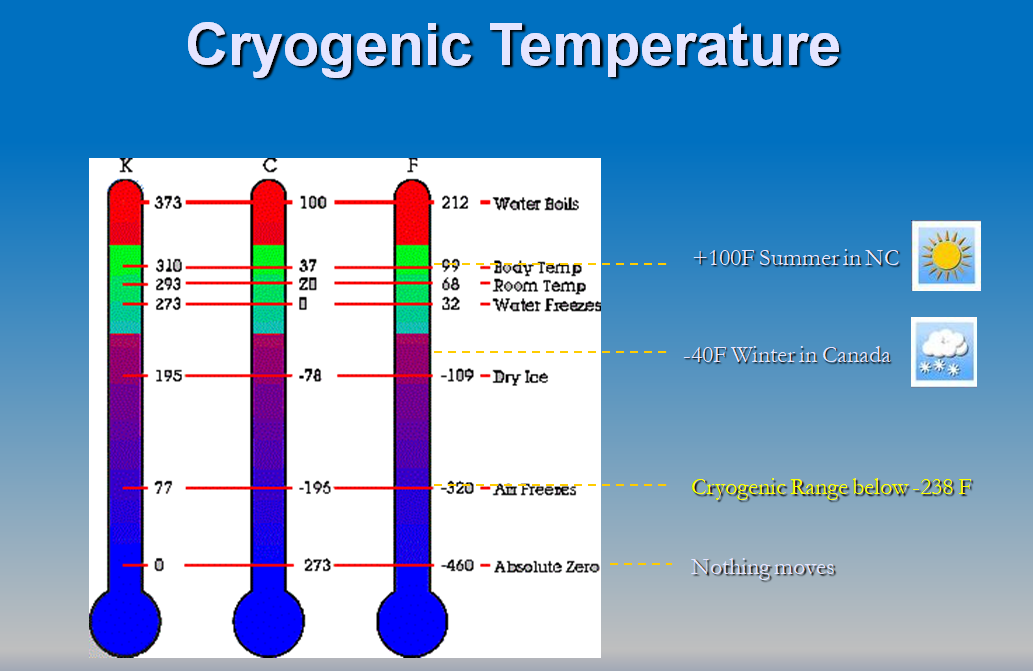

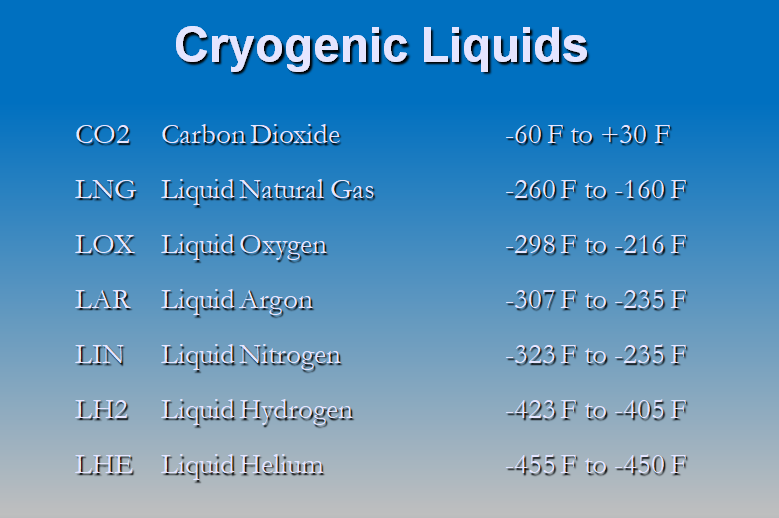

Cryogenic Flow Measurement

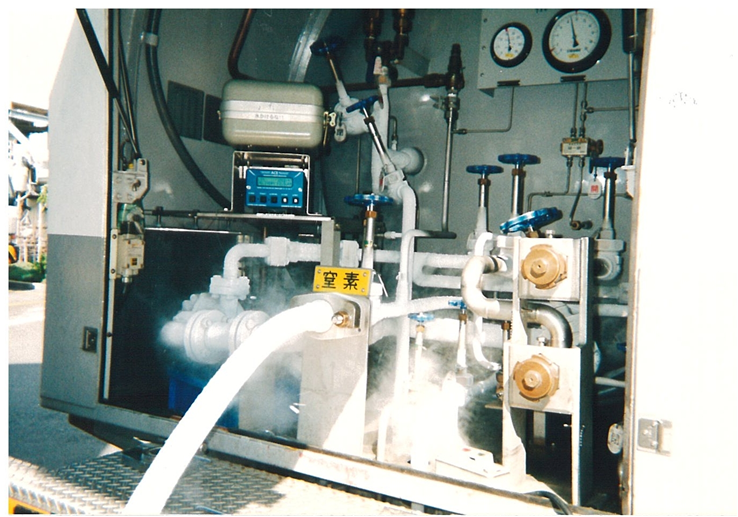

Truck Mounted System(ICE)

- Hoffer pioneered the truck-mounted turbine flow system 40 years ago

- 1000’s systems are in use worldwide

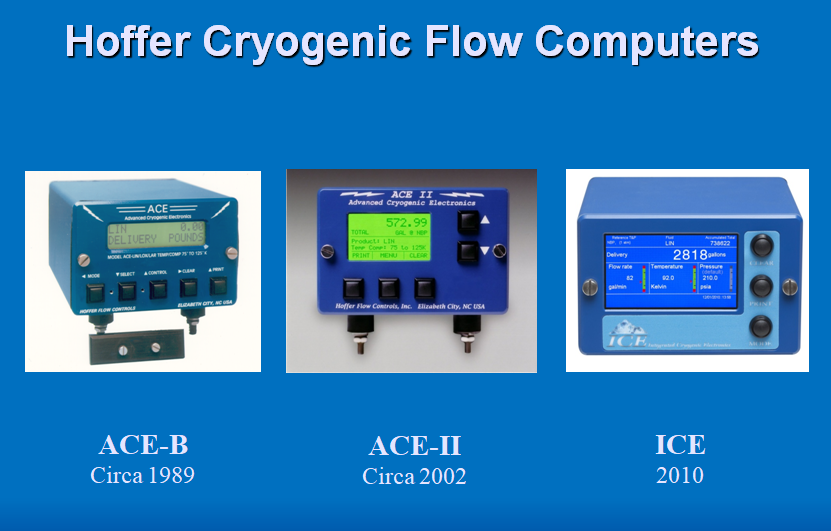

- ICE is the fifth generation of Hoffer truck-mounted flow computer

See: Hoffer Mobile App for Cryogenic ICE

Cryogenic Delivery Trucks

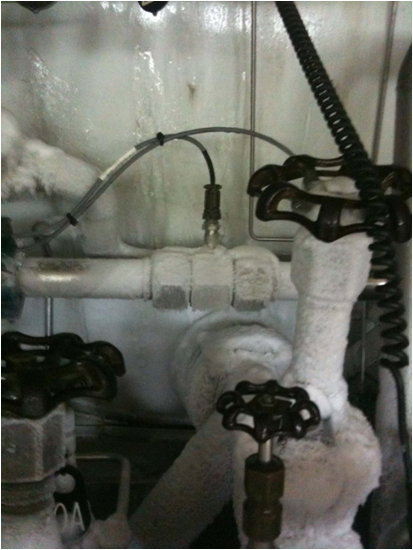

Cryogenic Installation

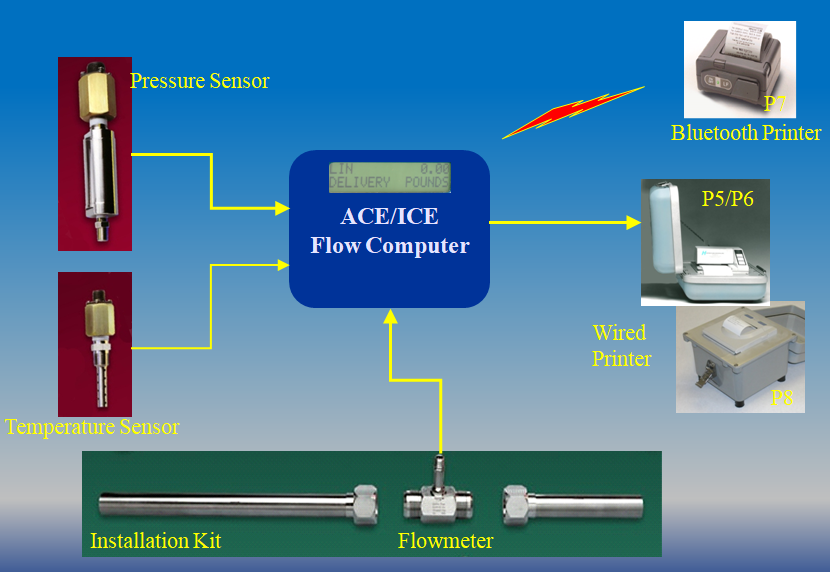

System Components

Why you “should” consider using turbine flowmeters!

Turbine Meter Advantages

Response Time

- Fast, dynamic response time

- Measured in milliseconds!

- Commonly used for rocket propulsion Shock, vibration & temp extremes. We pioneered the use of turbine flowmeters on cryogenic delivery trucks in the 1970s

- Suitable for installation on trucks subject to shock & vibration

- Subject to wide operating temperature extremes

- Our flow system is the “cash register” on many bulk delivery cryogenic trucks domestically and internationally Robust Design. Flowmeter “internals” were redesigned to meet “high shock” and “vibration” MIL standards for US Navy.

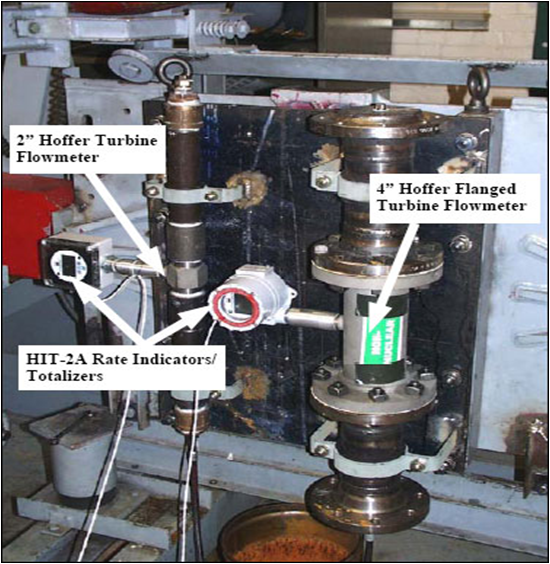

- Hoffer has supplied multiple-size turbine flowmeters built to meet MIL-STD-901D (shock-high impact) and MIL-STD-167-1 (vibration) for the US Navy.

Hoffer “Navy” version turbine flowmeter along with HIT-2A totalizer/rate indicator undergoing “shock” & vibration testing.

Navy Shock, Vibration & EMI Testing

Shipboard Applications include:

LPD Class Ships

HFC has supplied 1 1/2″ turbine flowmeters along with flowmeter signal conditioners (4 – 20 mA output) & rate indicators/totalizers for the LPD Class ship. Application is fuel supply for the main propulsion diesel engines.

LSD and DDG Class Ships

HFC has supplied 1/2″ & 3/4″ turbine flowmeters along with flowmeter signal conditioners(4 – 20 mA output) & rate indicators/totalizers for both classes of ships. Application is fuel supply for power generation.

DDG Class Ships

HFC has supplied flowmeters on both the supply and discharge sides of the reverse osmosis (R/O) system. The application is seawater on the supply side. Flowmeters are naval brass and monel. Discharge side flowmeters are standard 316 SS construction. The flow system enables the crew to determine the efficiency of the R/O system.

ACE/ICE Common features

- Flow, temperature, pressure, total delivery

- Volume, mass, and corrected volume.

- Pump Interlock output

- Malfunction/Faults warning messages

- Password protection

- Print delivery ticket

- Audit trail support

- Time and date stamp of delivery documents

- Trip log up to 100 deliveries

- Pulse security feature

- …and all are blue

- What is different?

ACE/ICE Functional Differences

| ACE-B | ACE-II | ICE | |

|---|---|---|---|

| Fluids | Fixed 1-3 | Programmable 4 | Programmable 12 |

| T&P

Accuracy |

8 bit

0.25% |

12 bit

0.025% |

12 bit

0.025% |

| Pump hours reminder | – | YES | YES |

| PC config. software | – | YES | YES |

| Languages | 1 | 3 | Multiple

5 implemented |

| Technology | 80’s | 90’s | 21st Century |

Why do customers hate ACE-II and love ICE?

It’s All About User Interface

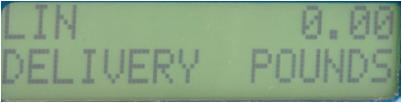

ACE-B

2 lines x 16 characters

ACE-II

B/W 128×64 pixels

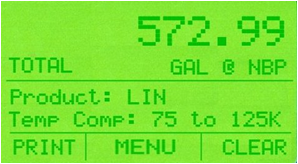

ICE

Color 480×272 pixels

Touch Screen

Company News

Company News