Wing Nut High-Pressure Flowmeters, Turbine Liquid Flowmeters

Wing Nut High-Pressure Flowmeters, Turbine Flowmeters Liquid Service

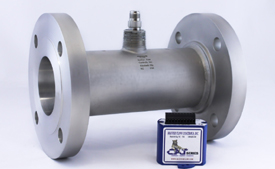

NEW! Hoffer Flow Controls is pleased to announce the availability of our 2″ size Wing Nut Series liquid, high-pressure flow meters, with expedited delivery times of typically 2 to 5 workdays. The 2″ size wing nut flow meters are available with tungsten carbide bearings and are suitable for clean liquids or slurry service. These meters are rated to working pressures of 15,000 PSI and include a 12 point NIST certified calibration.

OUTSTANDING FEATURES

- Wing Nut High Pressure (15,000 PSI) Turbine Flowmeters for Liquid Service

- Outstanding accuracy for Water, Liquid Carbon Dioxide, and Cement Slurry

SPECIFICATIONS

- Linearity:±0.5% of reading (±0.25% typical) over tabulated linear flow range.

- Repeatability: ±0.1% over tabulated useable range.

- Temperature Range: -450° to +450°F (Standard).

- Pressure Drop Characteristics: Request graphical data.

- Overrange:150% of maximum flow (intermittently).

- Construction: Housing – A286 alloy steel. Internals – All stainless steel (except “T” bearings). Rotor: 17.4 PH.

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Control on Linked In

Wing Nut High-Pressure Flowmeters | Hoffer Flow Controls

Hoffer Turbine Flowmeters are available in a broad range of standard and special materials. The wide range of construction options allows for selecting the optimum combination of useful range, corrosion resistance, and operating life for a particular application. A low mass rotor design allows for a rapid dynamic response which permits the turbine flowmeter to be used in pulsating flow applications. The deflector cones eliminate downstream thrust on the rotor and allow for hydrodynamic positioning of the rotor between deflector cones. The hydrodynamic positioning of the low mass rotor provides wider rangeability and longer bearing life than that of conventional turbine flowmeters. Integral flow straightening tubes minimize the effects of upstream flow turbulence. The housing is made of non-magnetic materials. The rotor is made of magnetic or magnetized material. Bearings are chosen based on service fluid, cost, and accuracy considerations.

Also, see

High-Pressure Flow Meter Solutions

Liquid Service Turbine Flow Meters, HO Series Autoclave

MF Series Turbine Flowmeters for Liquid

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News